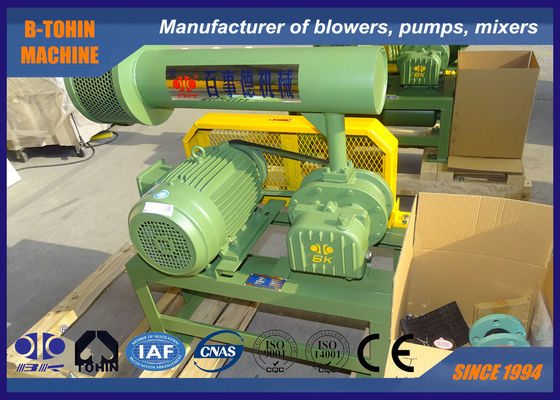

Positive Three Lobe Roots Blower, pressure 10-80KPA, rotary speed 700-1500rpm

Roots blower is widely used in electricity,petroleum,steel industry,smelling,food,oxygen making,spinning,

vacuum packing,paper making,aquaculture,sewage treatment,pneumatic conveying,etc.

Specifications:

|

Model

|

BK8016S

|

|

Air capacity

|

15.21-47.14m3/min

|

|

Discharge differential pressure

|

10-80KPA

|

|

Rotary speed

|

700-1500rpm

|

|

Motor type

|

30-90KW

380/400/415/440V, 3PHASES, 50/60HZ, frequency motor also available

|

|

Motor brand

|

Standard: Siemens Beide or Wannan motor

Siemens and ABB motor for your option

|

|

Installation type

|

Standard: horizontal type

Vertical type available for your option

|

| Color |

Customized, standard of RAL6011 |

|

N.W. of blower without motor

|

730 kg

|

|

Packing size Approx.

|

2.1*1.5*2.35 (length*width*height)

|

Features:

1. Helical type timing gears for smooth operation

2. Compact, flexibility in installation gives users more choices.

3. Adopt integral structure of impeller, more stable in operation.

4. Adopt imported oil seals made from fluoric rubber, which is of good wear resistance and high-temperature resistance.

5. Small vibration and economical energy consumption.

Parameter sheet

| Model |

Port Dia. (mm) |

Speed |

Inlet capacity (m3/min)and shaft power (KW) |

| 0.1kgf/cm2 |

0.2kgf/cm2 |

0.3kgf/cm2 |

0.4kgf/cm2 |

0.5kgf/cm2 |

0.6kgf/cm2 |

0.7kgf/cm2 |

0.8kgf/cm2 |

| 1000mmH2O |

2000mmH2O |

3000mmH2O |

4000mmH2O |

5000mmH2O |

6000mmH2O |

7000mmH2O |

8000mmH2O |

| 0.01Mpa |

0.02Mpa |

0.03Mpa |

0.04Mpa |

0.05Mpa |

0.06Mpa |

0.07Mpa |

0.08Mpa |

| rpm |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

m3/min |

KW |

| BK8016S |

150(6") |

700 |

20.17 |

11.16 |

18.75 |

13.93 |

17.67 |

16.69 |

16.75 |

19.45 |

15.94 |

22.21 |

15.21 |

24.98 |

|

|

|

|

| 850 |

25.23 |

13.55 |

23.81 |

16.91 |

22.72 |

20.26 |

21.81 |

23.62 |

21.00 |

26.97 |

20.27 |

30.33 |

19.59 |

33.68 |

|

|

| 1000 |

30.29 |

15.95 |

28.87 |

19.89 |

27.78 |

23.84 |

26.86 |

27.79 |

26.05 |

31.73 |

25.32 |

35.68 |

24.65 |

39.63 |

24.02 |

43.57 |

| 1150 |

35.34 |

18.34 |

33.93 |

22.88 |

32.84 |

27.42 |

31.92 |

31.95 |

31.11 |

36.49 |

30.38 |

41.03 |

29.71 |

45.57 |

29.08 |

50.11 |

| 1250 |

38.72 |

19.93 |

37.30 |

24.87 |

36.21 |

29.80 |

35.29 |

34.73 |

34.48 |

39.67 |

33.75 |

44.60 |

33.08 |

49.53 |

32.45 |

54.47 |

| 1400 |

43.77 |

22.33 |

42.35 |

27.85 |

41.26 |

33.38 |

40.35 |

38.90 |

39.54 |

44.43 |

38.81 |

49.95 |

38.14 |

55.48 |

37.51 |

61.00 |

| 1500 |

47.14 |

23.92 |

45.72 |

29.84 |

44.64 |

35.76 |

43.72 |

41.68 |

42.91 |

47.60 |

42.18 |

53.52 |

41.51 |

59.44 |

40.88 |

65.36 |

Manufacturing standards

The products provided by the supplier are manufactured according to the following standards:

JISB8341-1995 "Displacement compressor test and inspection method"

JB/T8941.1-1999 "Conditions for Roots Blower for General Application"

JB/T8941.2-1999 "Performance Test Method for Roots Blower for General Application "

GB/T 13306-91 GB / T 13306-91 "Nameplate"

Structure of blower main body

|

No.

|

Part Name

|

Qty.

|

|

No.

|

Part Name

|

Qty.

|

|

No.

|

Part Name

|

Qty.

|

|

1

|

Footing

|

2

|

|

9

|

Left end cover

|

1

|

|

17

|

Oil tank

|

1

|

|

2

|

Hexagon bolt

|

4

|

|

10

|

Round pin

|

4

|

|

18

|

Gear

|

2

|

|

3

|

Antidust seal

|

1

|

|

11

|

Housing

|

1

|

|

19

|

Key

|

2

|

|

4

|

Drive impeller

|

1

|

|

12

|

Oil seal

|

4

|

|

20

|

Axial sleeve

|

2

|

|

5

|

Drive end bearing

|

2

|

|

13

|

Right end cover

|

1

|

|

21

|

Gear end bearing

|

2

|

|

6

|

Driven impeller

|

2

|

|

14

|

Bolt

|

16

|

|

22

|

Bearing plate

|

2

|

|

7

|

Dust cover

|

1

|

|

15

|

Breather

|

1

|

|

23

|

Adjustable pad

|

several

|

|

8

|

Grease nipple

|

2

|

|

16

|

Mounting bolt

|

8

|

|

24

|

Magnetic nut

|

1

|

Assembling drawing of blower package

Standard supply of scope

1. bare shaft blower

2. relieve valve

3. slime type wafer check valve

4. inlet silencer(with air filter)

Damping silencer is adopted for mainly eliminating the airflow noise at the inlet of the blower. It is welded by outer cylinder, inner cylinder, flange and other parts, and the sound absorption material is placed between the inner and outer cylinders for light weight,low resistance and better noise reduction effect. The silencer is made of A3 steel.

5. discharge silencer

6. Blower and motor base (with belt cover)

7. rubber flexible joint and shock absorber

8. motor pulley

9. pressure meter

10. V-belt

11. bolts and nuts and other connection parts

12. electric motor

Optional parts such as acoustic enclosure, control cabinet, auto-start valve and spares are available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!