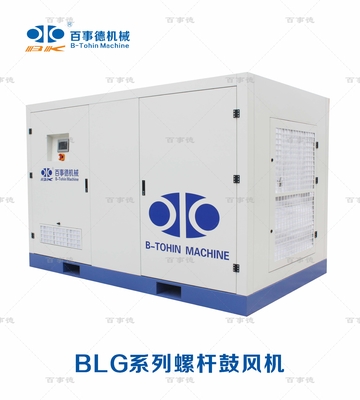

About Screw Blower

The screw blower achieves internal compression during the air transportation in the cavity, so the screw blower has most of the advantages of traditional blowers, and at the same time has higher efficiency.

The process of air transportation and compression is continuous and progressive, so the airflow pulsation is lower, and the exhaust noise and temperature control are better than traditional blowers.

As a new type of rotary blower developed in recent years, screw blowers have begun to be applied in aeration, gas-water back-washing, oxidative de-sulfurization, fluidization/homogenization process, and pneumatic conveying due to their simple structure, stability, energy saving and low noise.

Dimension and other data

| Model |

BLG300RB |

| Lenght (mm) |

3000 |

| Width (mm) |

2000 |

| Height (mm) |

1900 |

| Outlet size |

DN300 |

| Weight (kg) |

3200 |

| Noise (dB) |

86 |

Composition

The screw blower is composed of blower enclosure, blower main body, motor, air filter, silencer, an oil pump tank and oil filter.

As the core component of the screw blower, the structure of the blower main body directly determines the blower’s performance. The main body is composed of casing, screw rotors, gear box, bearings, shaft seals, ect.

Working Principle

The operating principle of the screw blower is that two parallel female and male rotors mesh with each other in the "∞"-shaped cylinder to form a working volume. Through the synchronous gear, the rotor rotates at high speed in the opposite direction, and the working volume changes periodically as the rotor rotates, realizing air compression during air transportation. The working cycle of screw blower can be divided into three processes: suction, compression and exhaust. The cycle process is as follows:

1. Suction process

Picture ① : The air enters the volume between the teeth of the rotor through the suction port. As the rotor rotates, the volume between the teeth continuously expands.

Picture ② : When the volume between the teeth reaches the maximum, the volume between the teeth is disconnected from the suction port and the suction process ends.

2. Compression process

Picture ③: during compressing

3. Exhaust process

Picture ④: After the inter-tooth volume is connected to the exhaust port, the exhaust process begins. During the rotation of the rotor, the volume between the teeth continuously decreases, sending the compressed air to the exhaust pipe. This process continues until the volume reaches designed data.

Features:

Low energy consumption

By adopting the principle of thermal adiabatic compression, the oil-free screw blower’s total efficiency is higher than 75%, and is 20%-35% higher than traditional blowers. Also it is featured with higher exhaust pressure and lower pressure pulse.

Low noise

The aerodynamic noise of the screw rotor is very small, and the output is stable, which eliminates the sudden release of internal air. The wave-shaped inlet and the vent minimize the airflow fluctuations, and the noise of the blower is less than that of the traditional type.

Intelligent Control

Intelligent PLC control, remote control and multiple communication modes are available, which is convenient for operation and maintenance.

Low cost

The optimized structural design enables less energy consumption and ensures the durability of the product. At the same time, the unit of light wight (load) runs smoothly without special infrastructure so that save cost for customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!