Screw Blower Introduction

BLG Permanent Magnet Variable Frequency Screw Blower is an advanced compressed air system designed for energy efficiency and precise control in industrial applications. This blower combines cutting-edge motor and drive technology with robust screw compression, making it ideal for industries

prioritizing energy savings, operational flexibility, and reliability. Its design addresses modern needs for sustainability and cost-effective performance in dynamic environments.

Screw Blower Specifications

| Self- lubricationⅡ | Pressure Range | 40-100KPa | Airflow Range | 1.4-172m³/min | Power Range | 4-280kw |

| No. | Model | Diameter | Exhaust Pressure (KPa) | Airflow (m³/min) | Motor Power (Kw) | Main Body Speed (rpm) |

| 1 | BLG160B | DN150 | 40-100 | 10-20 | 11-37 | 2000-3000 |

Working Principle

A rotary screw compressor using twin meshing screws for positive displacement air compression.Provides smooth, pulsation-free airflow with lower vibration/noise compared to piston blowers.

Main characteristics

1,The male and female rotors of oil-free screw blower are precisely designed. Compared with roots blower,it can achieve internal compression in the cavity,with higher efficiency and 20% higher energy saving performance under the same energy consumption conditions.

2,Stable airflow,less airflow fluctuation when pressure changes.

3,Applicable to higher pressure ,low noise.

4,Available with PLC intelligent remote control and different communication methods, convenient for operation management.

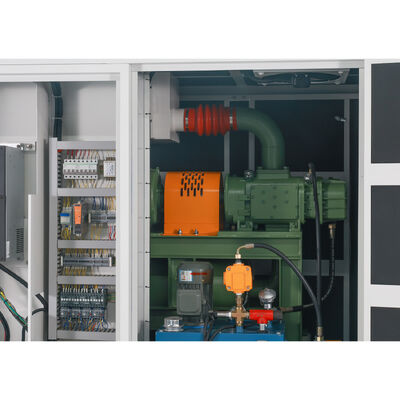

Component characteristics

1,Screw Host

Efficient profile rotor design.

Adopting national standard level 5 precision synchronous gears and driving gears.

Innovative bearing arrangement, using fixed radial and axial bearings, increases service life.

Piston ring seal+magnetic seal to achieve oil and gas separation between compression chamber and lubrication chamber.

2,Permanent Magnet Motor

Magnetic field properties, can maintain its magnetic field without external energy.

High efficiency and energy-saving, with an average efficiency of 75% to 80% within the speed range of 1000-3600r/min.

High voltage stabilization accuracy can extend the service life of the battery.

No electric brushes, no collector rings, and no electric sparks generated during operation, so there is no wireless interference, greatly improving performance.

3,Operating control system

Integrated workstation monitoring instruments, signal control modules, frequency converters, touch screens, etc., no additional installation required.

Optimize the selection of driving components, parameter settings can accurately achieve high efficiency.

Fully equipped with automatic control and protection functions, while achieving online and remote control.

Applications

Wastewater Treatment: Variable aeration demands in biological processes.

Industrial Processes: Pneumatic conveying, fermentation, or manufacturing requiring stable airflow.

HVAC Systems: Efficient air handling in large facilities.

Advantages

Energy Efficiency: PMSM + VFD reduces energy consumption by 10% compared to fixed-speed systems.

Precision Control: Real-time adjustments optimize performance for varying demands (e.g., aeration in wastewater treatment).

Lower Maintenance: Fewer moving parts and reduced wear from soft starts and stable operation.

Environmental Benefits: Lower carbon footprint and potential eligibility for energy-saving incentives.

Main machine

About Us

①In 1994,Yixing Pengde Machinery Co.,Ltd. ( a Sino-Japanese joint Venture) was born,and relocated in the Industrial Park for Environmental SCI and TECH. The following year with company name changed to B-Tohin Machine (Jiangsu)Co.,Ltd.

②Localization of HC blower in 1996

③In 1999,established a joint venture named Tohin Machine Co.,Ltd. with TUTHILL Pneumatics Group (United States).

④Localization and mass sales of BK blower in 2000

⑤In 2004,HC Blower and BK Blower got the honor of “new high-tech product”,and the company was rated as a high-tech enterprise. In the same year,the company passed ISO9001 certification,purchased more than 30000 square meters for new plant and donated 500000 yuan to build the B-Tohin Qinghu Hope Middle School.

⑥In 2009,the single-stage high-speed blower was successfully launched, and BK was rated as famous trademark of Wuxi City and famous trademark of Jiangsu Province.The torch program project of Jiangsu Province and a number of patents were achieved ,also the company’s together-with-heart idea: attentively,sincerely,confidently was put forward.

⑦The company’s BK brand was rated as “China Well-known Trademark” in 2013.

⑧In 2014,the company was identified as “Jiangsu Aerodynamic Research Center” by the Science &Technology Department of Jiangsu Province,and got the ISO14001 certificate.At the same time,Office Automation was put into use successfully.

⑨In 2015,the company introduced a whole blower performance test system.Successfully bid for the 2600 square meters industrial assets in Yixing economic development zone and established Wuxi B-Tohin Blower Technology Co.,Ltd.

⑩In 2016, Sino-Korean joint venture Wuxi B-Tohin & Ace Blower Science and Technology Co.,Ltd. was established. In the same year,air foil centrifugal blower was successfully introduced,and Tohin Vietnam Industry was founded.

⑪In 2017,the company turned on the Internet of things intelligent ,the balance tester of Air Bearing Turbo Centrifugal blower was successfully put into use .The Science and Technology Association of B-Tohin was founded.

⑫In 2018, B-Tohin magnetic suspension centrifugal blower,stainless steel blower and other new products were successfully launched.

⑬In2019,Adopted the ERP platform management in the whole company and passed the assessment of “Informational and Industrialize Integration” in 2019.

⑭B-Tohin screw blower was put on market successfully in 2021.

⑮Launched contract energy management and new type product lease sales in 2022.With a new area of 75000 square meters acquired, the project of design and intelligent manufacturing base of high efficiency blower and office building of B-Tohin started.

The new factory building was successfully completed and relocated.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!