Screw Blower Introduction

BLG Permanent Magnet Variable Frequency Screw Blower is an advanced compressed air system designed for energy efficiency and precise control in industrial applications. This blower combines cutting-edge motor and drive technology with robust screw compression, making it ideal for industries prioritizing energy savings, operational flexibility, and reliability. Its design addresses modern needs for sustainability and cost-effective performance in dynamic environments.

Screw Blower Specifications

| Model |

BLG160A |

| Diameter |

DN150 |

|

Exhaust Pressure (KPa)

|

40-100 |

| Airflow(m³/min) |

7.1-15.1 |

| Motor Power ( kw) |

7.5-30 |

| Main Body Speed(rpm) |

2000-3300 |

Working Principle

A rotary screw compressor using twin meshing screws for positive displacement air compression.Provides smooth, pulsation-free airflow with lower vibration/noise compared to piston blowers.

Main characteristics

1,The male and female rotors of oil-free screw blower are precisely designed. Compared with roots blower,it can achieve internal compression in the cavity,with higher efficiency and 20% higher energy saving performance under the same energy consumption conditions.

2,Stable airflow,less airflow fluctuation when pressure changes.

3,Applicable to higher pressure ,low noise.

4,Available with PLC intelligent remote control and different communication methods, convenient for operation management.

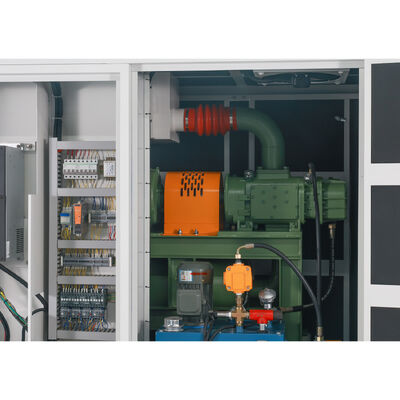

Component characteristics

1,Screw Host

Efficient profile rotor design.

Adopting national standard level 5 precision synchronous gears and driving gears.

Innovative bearing arrangement, using fixed radial and axial bearings, increases service life.

Piston ring seal+magnetic seal to achieve oil and gas separation between compression chamber and lubrication chamber.

2,Permanent Magnet Motor

Magnetic field properties, can maintain its magnetic field without external energy.

High efficiency and energy-saving, with an average efficiency of 75% to 80% within the speed range of 1000-3600r/min.

High voltage stabilization accuracy can extend the service life of the battery.

No electric brushes, no collector rings, and no electric sparks generated during operation, so there is no wireless interference, greatly improving performance.

3,Operating control system

Integrated workstation monitoring instruments, signal control modules, frequency converters, touch screens, etc., no additional installation required.

Optimize the selection of driving components, parameter settings can accurately achieve high efficiency.

Fully equipped with automatic control and protection functions, while achieving online and remote control.

Applications

Wastewater Treatment: Variable aeration demands in biological processes.

Industrial Processes: Pneumatic conveying, fermentation, or manufacturing requiring stable airflow.

HVAC Systems: Efficient air handling in large facilities.

Advantages

Energy Efficiency: PMSM + VFD reduces energy consumption by 10% compared to fixed-speed systems.

Precision Control: Real-time adjustments optimize performance for varying demands (e.g., aeration in wastewater treatment).

Lower Maintenance: Fewer moving parts and reduced wear from soft starts and stable operation.

Environmental Benefits: Lower carbon footprint and potential eligibility for energy-saving incentives.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!