About Screw Blower

BLG Permanent Magnet Variable Frequency Screw Blower is an advanced compressed air system designed for energy efficiency and precise control in industrial applications. This blower combines cutting-edge motor and drive technology with robust screw compression, making it ideal for industries

prioritizing energy savings, operational flexibility, and reliability. Its design addresses modern needs for sustainability and cost-effective performance in dynamic environments.

| Self- lubricationⅡ |

Pressure Range |

40-100KPa |

Airflow Range |

1.4-172m³/min |

Power Range |

4-280kw |

| No. |

Model |

Diameter |

Exhaust Pressure

(KPa)

|

Airflow

(m³/min)

|

Motor Power

(Kw)

|

Main Body Speed

(rpm)

|

| 1 |

BLG109A |

DN65 |

40-100 |

1.4-2.9 |

4-7.5 |

2000-3000 |

| 2 |

BLG109B |

2.2-4.8 |

4-11 |

| 3 |

BLG127B |

DN100 |

3.9-8.7 |

5.5-18.5 |

| 4 |

BLG140B |

6.4-12.3 |

7.5-22 |

| 5 |

BLG160A |

DN150 |

7.1-15.1 |

7.5-30 |

| 6 |

BLG160B |

10-20 |

11-37 |

| 7 |

BLG172B |

11.5-25 |

15-45 |

| 8 |

BLG202A |

DN200 |

17.5-31.7 |

18.5-55 |

| 9 |

BLG202B |

22.8-41 |

22-75 |

| 10 |

BLG240A |

DN250 |

27.4-47.7 |

30-90 |

1800-3000 |

| 11 |

BLG240B |

34.5-60 |

37-110 |

| 12 |

BLG275A |

DN300 |

40.7-75.5 |

37-132 |

| 13 |

BLG275B |

47.4-90 |

45-160 |

| 14 |

BLG315A |

DN350 |

67.6-116.7 |

75-185 |

| 15 |

BLG315B |

76.4-132 |

75-220 |

| 16 |

BLG343A |

DN350 |

73-136 |

75-200 |

| 17 |

BLG343B |

DN450 |

94-172 |

90-280 |

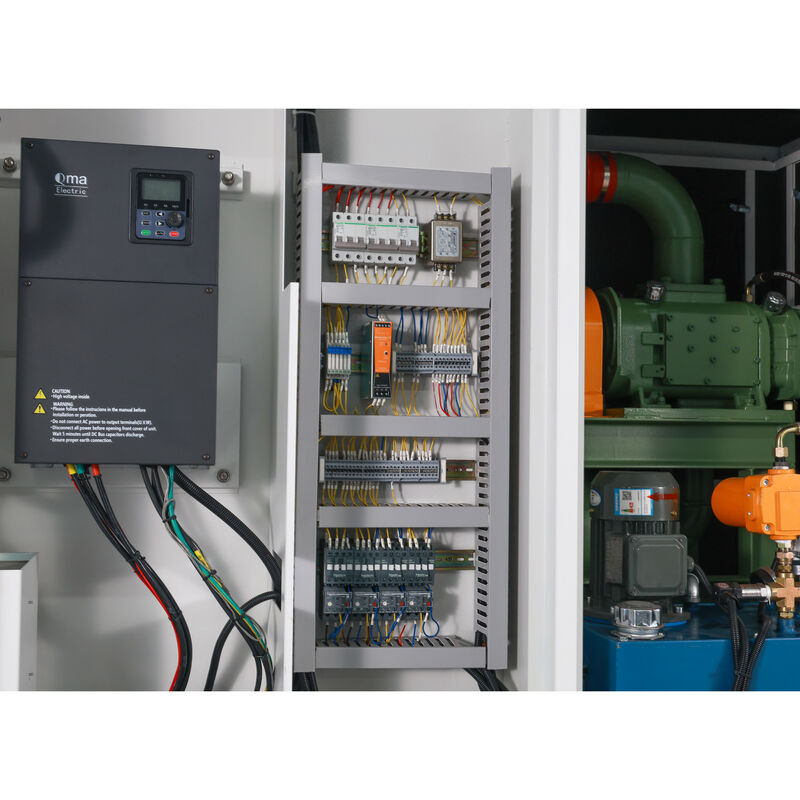

Composition

The screw blower is composed of blower enclosure, blower main body, motor, air filter, silencer, an oil pump tank and oil filter.

As the core component of the screw blower, the structure of the blower main body directly determines the blower’s performance. The main body is composed of casing, screw rotors, gear box, bearings, shaft seals, ect.

Working Principle

The operating principle of the screw blower is that two parallel female and male rotors mesh with each other in the "∞"-shaped cylinder to form a working volume. Through the synchronous gear, the rotor rotates at high speed in the opposite direction, and the working volume changes periodically as the

rotor rotates, realizing air compression during air transportation. The working cycle of screw blower can be divided into three processes: suction, compression and exhaust. The cycle process is as follows:

1. Suction process

Picture ① : The air enters the volume between the teeth of the rotor through the suction port. As the rotor rotates, the volume between the teeth continuously expands.

Picture ② : When the volume between the teeth reaches the maximum, the volume between the teeth is disconnected from the suction port and the suction process ends.

2. Compression process

Picture ③: during compressing

3. Exhaust process

Picture ④: After the inter-tooth volume is connected to the exhaust port, the exhaust process begins. During the rotation of the rotor, the volume between the teeth continuously decreases, sending the compressed air to the exhaust pipe. This process continues until the volume reaches designed data.

Main characteristics

1,The male and female rotors of oil-free screw blower are precisely designed. Compared with roots blower,it can achieve internal compression in the cavity,with higher efficiency and 20% higher energy saving performance under the same energy consumption conditions.

2,Stable airflow,less airflow fluctuation when pressure changes.

3,Applicable to higher pressure ,low noise.

4,Available with PLC intelligent remote control and different communication methods, convenient for operation management.

Applications

Wastewater Treatment: Variable aeration demands in biological processes.

Industrial Processes: Pneumatic conveying, fermentation, or manufacturing requiring stable airflow.

HVAC Systems: Efficient air handling in large facilities.

Specifications to Consider

1,Airflow capacity (m³/min or CFM)

2,Pressure range (bar or psi)

3,Motor power rating (kW) and efficiency class (e.g., IE5)

4,Noise levels (dB) and cooling method (air/water-cooled).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!